Have you ever wondered how Indian rug manufacturing maintains such high quality? Look no further, because in this informative blog post, we will be exploring the world of Indian rug manufacturing and discovering the secrets behind their exceptional quality assurance. Whether you’re a curious reader or someone in need of Indian home furnishings, Sheeltex India is here to provide you with all the information and assistance you need. So sit back, relax, and join us on this exciting journey into the realm of Indian rug manufacturing.

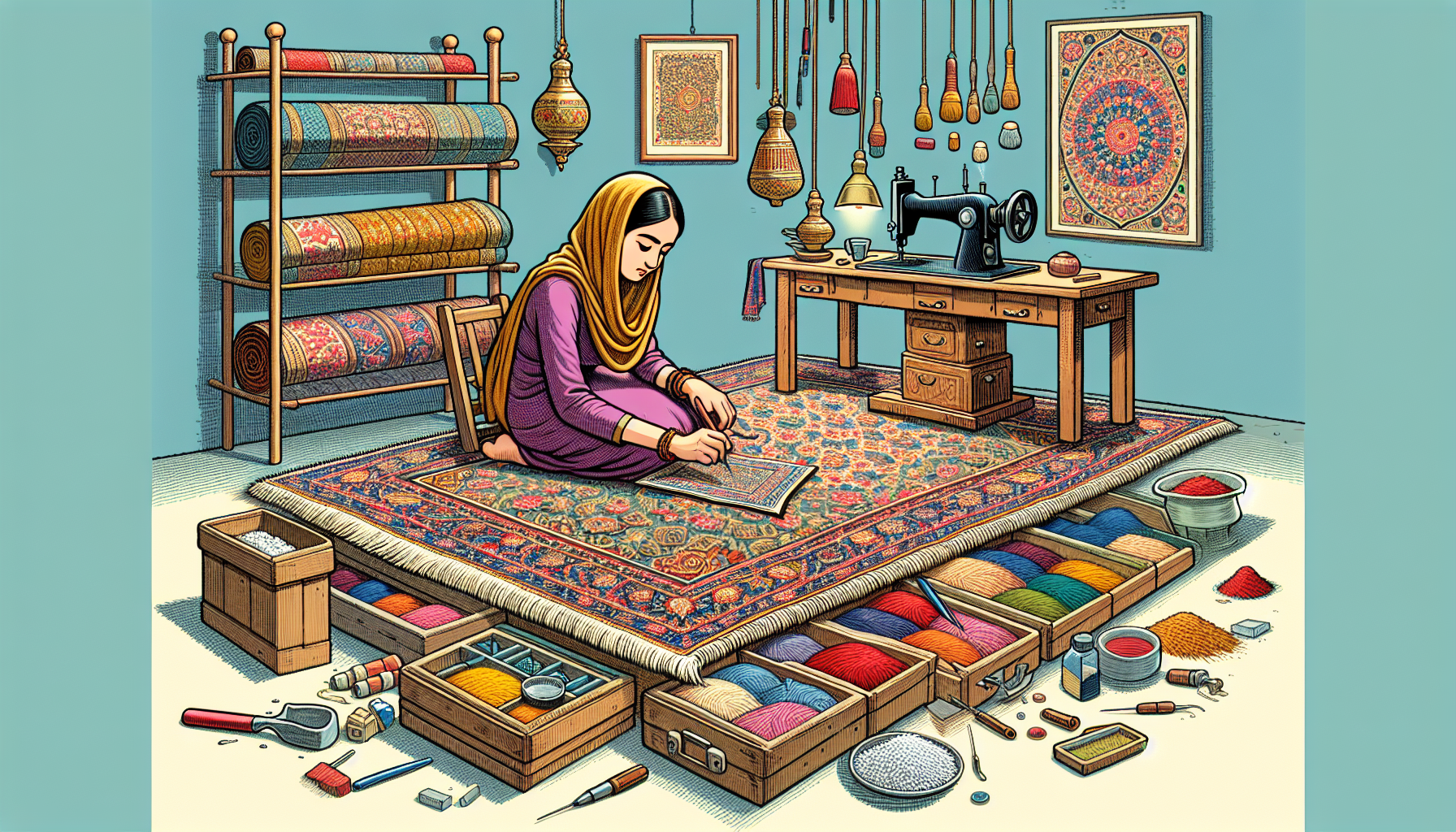

Overview of Indian Rug Manufacturing

Indian rug manufacturing has a rich history and is known for its intricate designs and high-quality craftsmanship. From the ancient times of the Mughal Empire to the present day, India has been a hub for rug production. The industry has grown and evolved over the years, adapting to modern technology and international market demands.

History of Indian Rug Manufacturing

The history of Indian rug manufacturing dates back several centuries. It was during the Mughal period in the 16th and 17th centuries that Indian rug weaving flourished. The Mughal emperors greatly contributed to the development of rug designs and techniques, blending Persian and Indian motifs to create unique patterns. The art of rug weaving was passed down from generation to generation, and today, India is renowned for its skilled artisans and their ability to create intricate designs.

The importance of quality assurance in Indian rug manufacturing

Quality assurance is of utmost importance in the Indian rug manufacturing industry. With the rising demand for Indian rugs in international markets, it is crucial to maintain high standards in terms of material quality, design, and craftsmanship. By ensuring consistent quality, manufacturers can build a reputation for excellence and establish long-lasting relationships with customers. Moreover, quality assurance plays a vital role in preserving the heritage and artistry associated with Indian rug manufacturing.

Key players in the Indian rug manufacturing industry

The Indian rug manufacturing industry is comprised of various key players, each contributing to the overall production and distribution of rugs. From large-scale manufacturers to small artisanal cooperatives, the industry is diverse and dynamic. Some renowned names in the industry include Sheeltex India, which is known for its commitment to quality and craftsmanship. These key players not only produce high-quality rugs but also collaborate with international markets to promote Indian home furnishings globally.

Quality Control Process in Indian Rug Manufacturing

Ensuring the highest level of quality in Indian rug manufacturing involves a comprehensive quality control process. From the selection of raw materials to the final inspection, each step is carefully monitored to meet the industry’s standards.

Raw material selection and inspection

The quality of raw materials used in rug manufacturing greatly affects the final product. Skilled artisans and manufacturers carefully select fibers, such as wool or silk, ensuring they meet the desired quality parameters. Rigorous inspections are conducted to identify any defects, such as uneven texture or discoloration, ensuring only the finest materials are used in the production process.

Design and pattern creation

Design and pattern creation are crucial steps in rug manufacturing. Experienced designers work closely with skilled artisans to bring intricate patterns to life. Traditional and contemporary designs are meticulously translated onto paper or digital platforms, taking into consideration color combinations, symmetry, and size. This step requires attention to detail and precision to achieve the desired aesthetic.

Dyeing and color quality control

Color plays a vital role in rug manufacturing, as it enhances the beauty and appeal of the final product. Dyeing is a complex process that requires expertise to ensure color consistency and vibrancy. Quality control measures are implemented to test colorfastness, ensuring the dyes used are resistant to fading. This step is crucial to maintain the integrity of the design and long-term durability of the rug.

Weaving and knotting process

The weaving and knotting process is where the true craftsmanship of Indian rug manufacturing shines. Highly skilled weavers use traditional hand-looms or advanced machinery to meticulously weave each thread, knot by knot. This step requires precision and attention to detail to achieve the desired pattern and texture. Quality control experts closely monitor the weaving process, ensuring consistency and accuracy.

Finishing and washing

Once the weaving process is complete, the rug goes through a finishing and washing stage. This includes trimming excess threads, securing the edges, and inspecting for any imperfections. The rugs are then subjected to a thorough washing process, using environmentally friendly detergents, to remove any dirt or impurities. This step ensures a clean and presentable final product.

Inspection and testing

The final stage of the quality control process involves a meticulous inspection and testing of the finished rug. Trained professionals carefully examine each rug for any defects or flaws, such as loose threads or uneven weaving. Special attention is given to the overall appearance, texture, and size of the rug. Testing for colorfastness, durability, and other quality parameters is also conducted to ensure the rug meets the desired standards.

Role of Technology in Quality Assurance

Technology plays a vital role in maintaining quality assurance in Indian rug manufacturing. With advancements in machinery, equipment, and digital tools, manufacturers can enhance the efficiency and accuracy of their quality control processes.

Utilization of advanced machinery and equipment

The use of advanced machinery and equipment in rug manufacturing has revolutionized the industry. Computerized looms allow for precise weaving and knotting, ensuring consistent patterns and textures. High-speed drying machines facilitate faster production and minimize the risk of moisture-related issues. By utilizing these technologies, manufacturers can increase productivity while maintaining high standards of quality.

Automated quality control systems

Automated quality control systems have become indispensable in the rug manufacturing industry. These systems use advanced sensors and cameras to detect defects or inconsistencies in the production process. They can identify issues such as incorrect weaving patterns, color variations, or uneven threading. By automating these quality control processes, manufacturers can minimize human error and ensure consistent quality throughout the production line.

Digital design and pattern creation

Digital tools have transformed the design and pattern creation process in rug manufacturing. Designers can now create intricate patterns using computer-aided design (CAD) software, allowing for greater precision and customization. Digital platforms also facilitate easier collaboration between designers and artisans, streamlining the communication and production process. This technological advancement has expanded the possibilities and creativity in rug manufacturing.

Testing and inspection tools

Advanced testing and inspection tools enable manufacturers to assess the quality of rugs accurately. Colorimeters and spectrophotometers measure color consistency and accuracy, ensuring the desired hues are achieved. Tensile testers evaluate the strength and durability of the rug’s fibers and construction. These tools aid in identifying any potential weaknesses or defects, allowing for timely adjustments and improvements.

Implementing International Standards

Indian rug manufacturers recognize the importance of adhering to international quality standards. By complying with these standards, they can build trust and credibility in the global market.

Adherence to international quality standards

Indian rug manufacturers strive to meet international quality standards, such as ISO 9001:2015. These standards encompass various aspects of manufacturing, including design, production, and quality management systems. By adhering to these standards, manufacturers can ensure consistent quality and customer satisfaction.

Certifications and accreditations

Obtaining certifications and accreditations is crucial for Indian rug manufacturers to demonstrate their commitment to quality assurance. Certifications such as RugMark and GoodWeave verify that rugs are produced without child labor and meet ethical and social responsibility standards. Compliance with these certifications helps build trust among customers, ensuring their rugs are ethically sourced and produced.

Compliance with ethical and sustainability regulations

Indian rug manufacturers are increasingly embracing ethical and sustainable practices. They aim to minimize their environmental impact and ensure fair treatment for their artisans. By using eco-friendly materials, reducing water and energy consumption, and implementing waste management and recycling initiatives, manufacturers contribute to a more sustainable future.

Training and Skill Development

Training and skill development programs play a crucial role in maintaining and improving the quality of Indian rug manufacturing.

Crafting artisans and weavers

Skilled artisans and weavers are the backbone of Indian rug manufacturing. Training programs are focused on preserving traditional techniques and enhancing the craftsmanship of these individuals. Through apprenticeships and vocational training, artisans gain the necessary skills and knowledge to create intricate designs and weave rugs with precision.

Technical training for quality control personnel

Quality control personnel play a vital role in maintaining and assuring the quality of Indian rugs. Training programs equip them with the expertise to conduct effective inspections, tests, and identify potential defects. They learn to use advanced machinery, testing equipment, and develop an understanding of international quality standards. Continuous training helps keep them updated with the latest advancements in technology and quality control practices.

Continual education and upskilling initiatives

The rug manufacturing industry is ever-evolving, and continual education is essential for artisans and manufacturers to stay ahead. Workshops, seminars, and collaborative initiatives help artisans and manufacturers expand their knowledge base and improve their skills. By staying abreast of the latest design trends, market demands, and technological advancements, they can innovate and meet the evolving needs of customers.

Supply Chain Management

Efficient supply chain management is crucial for maintaining quality assurance in Indian rug manufacturing.

Supplier evaluation and selection

Careful evaluation and selection of suppliers is vital to ensure the quality of raw materials. Indian rug manufacturers work closely with suppliers to ensure that the fibers and dyes they provide meet the desired standards. Regular assessments help maintain strong relationships with suppliers and ensure consistent quality throughout the supply chain.

Raw material traceability

Raw material traceability is an important aspect of supply chain management in rug manufacturing. Manufacturers must be able to trace the origin of each raw material used in the production process. This ensures transparency and allows for quality control throughout the supply chain. Traceability also helps address any potential issues or recalls that may arise.

Monitoring and feedback mechanisms

Establishing effective monitoring and feedback mechanisms allows manufacturers to identify and address any potential quality-related issues. Regular communication with suppliers, artisans, and distributors helps in gathering feedback and addressing concerns in real-time. This proactive approach enables manufacturers to continuously improve and maintain high-quality standards.

Customer Feedback and Satisfaction

Customer feedback is invaluable in maintaining quality assurance in Indian rug manufacturing. By actively seeking feedback and addressing customer concerns, manufacturers can improve their products and services.

Customer surveys and feedback collection

Regular customer surveys and feedback collection mechanisms are essential for understanding customer preferences and experiences. Through online surveys, questionnaires, and customer feedback forms, manufacturers gather valuable insights about their rugs. This feedback helps identify areas for improvement and informs product development and quality control processes.

Addressing customer complaints and issues

Addressing customer complaints and issues promptly is a top priority for Indian rug manufacturers. Timely response and resolution of customer concerns demonstrate a commitment to customer satisfaction. Manufacturers have dedicated customer support teams that handle complaints and work towards resolving any issues that arise. This proactive approach helps build trust and loyalty among customers.

Continuous improvement based on customer inputs

Customer feedback serves as a source of inspiration and improvement for Indian rug manufacturers. By analyzing customer inputs and suggestions, manufacturers can identify trends and areas for improvement. Continuous innovation and product development based on customer preferences help manufacturers meet changing market demands and maintain high-quality standards.

Environmental Sustainability Practices

Environmentally sustainable practices are essential in Indian rug manufacturing to minimize the industry’s impact on the environment.

Choosing eco-friendly materials and dyes

Indian rug manufacturers are increasingly opting for eco-friendly materials and dyes. Natural fibers, such as organic wool and silk, are sourced sustainably and do not harm the environment. Natural dyes derived from plants and vegetables are being preferred over synthetic dyes, reducing the use of harmful chemicals.

Reducing water and energy consumption

Efforts are being made to reduce water and energy consumption in rug manufacturing. Water-saving technologies and processes are implemented, such as recycling and reusing water used in the dyeing and washing processes. Energy-efficient machinery and lighting are utilized to minimize energy consumption and reduce the carbon footprint.

Waste management and recycling initiatives

Waste management and recycling initiatives are integral to sustainable rug manufacturing. Efforts are made to minimize waste during production, and any scrap materials are recycled or repurposed. Manufacturers work towards implementing recycling programs for packaging materials, ensuring responsible waste management throughout the production process.

Ensuring Ethical Manufacturing Practices

Ethical manufacturing practices are given high priority in Indian rug manufacturing to ensure fair treatment and support for artisan communities.

Fair treatment and wages for artisans

Indian rug manufacturers prioritize fair treatment and wages for artisans. They actively promote a safe and healthy work environment, ensuring that artisans are paid a fair wage for their skilled craftsmanship. By valuing the contributions of artisans, manufacturers sustain the traditional art forms and support the livelihoods of communities.

No child labor policies

Indian rug manufacturers strictly adhere to no child labor policies. They ensure that their supply chain is free from the exploitation of child labor. Regular audits and inspections are conducted to verify compliance with these policies. The welfare and education of young individuals are prioritized to create a sustainable and ethical manufacturing industry.

Support for artisan communities

Indian rug manufacturers actively support artisan communities through various initiatives. They collaborate with cooperatives or self-help groups to empower artisans and enhance their skills. Manufacturers provide training opportunities, access to better resources, and fair trade practices. This support helps preserve traditional craftsmanship and improve the socio-economic conditions of artisan communities.

Looking Towards the Future

The future of Indian rug manufacturing holds immense possibilities for growth and innovation.

Innovation in materials and designs

Indian rug manufacturers are continuously exploring innovative materials and designs to meet evolving market demands. Experimenting with sustainable and alternative fibers, such as bamboo or recycled materials, is becoming more prevalent. Contemporary designs and collaborations with modern designers help in creating rugs that appeal to a wider audience.

Investment in research and development

Investment in research and development is crucial for the long-term growth of the Indian rug manufacturing industry. Manufacturers are dedicating resources to develop new techniques, improve processes, and enhance overall quality. Research collaborations with academic institutions and industry experts help drive innovation and keep Indian rug manufacturing at the forefront of the global market.

Collaboration with international markets

Indian rug manufacturers are actively collaborating with international markets to expand their reach. By understanding the preferences and demands of different cultures, manufacturers can create rugs tailored to specific markets. Collaborations with international designers and distributors help promote Indian home furnishings globally, increasing the presence and recognition of Indian rug manufacturing.

In conclusion, Indian rug manufacturing industry places great emphasis on quality assurance to meet the demands of international markets. Through a rigorous quality control process, adherence to international standards, utilization of technology, training, and sustainable practices, Indian rug manufacturers are able to produce high-quality rugs that are renowned for their beauty and craftsmanship. As the industry looks towards the future, innovation, investment in research and development, and collaboration with international markets will continue to play a crucial role in maintaining and elevating the standards of Indian rug manufacturing. With the commitment of key players like Sheeltex India, the Indian rug manufacturing industry stands poised for continued success and growth.